SCADA + PLC Integration Checklist: A Complete Guide for Modern Automation

- PLC Play Ground

- 0

- Posted on

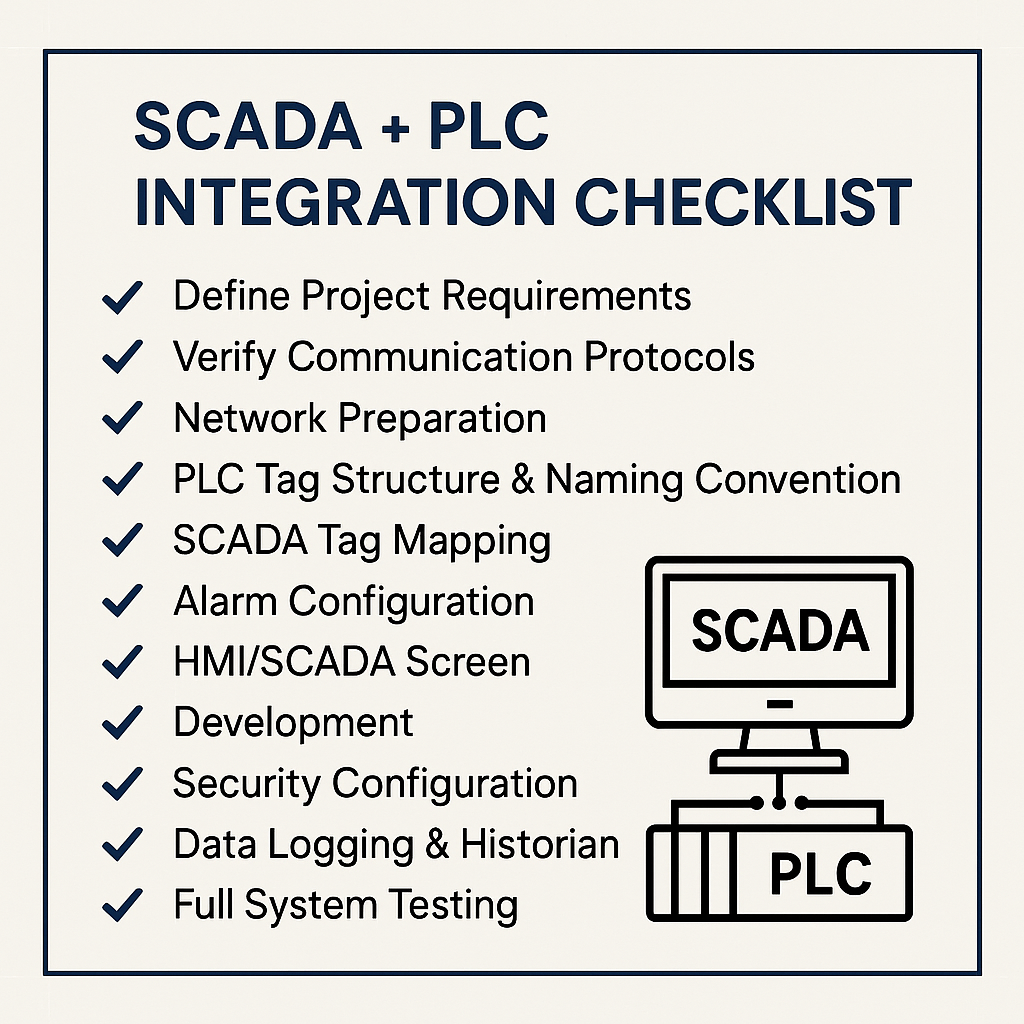

SCADA + PLC Integration Checklist

Integrating a SCADA system with PLCs is one of the most important steps in building a modern, reliable, and scalable industrial automation environment. A properly executed integration improves visibility, reduces downtime, and allows operators to make faster, data-driven decisions.

To help technicians, engineers, and system integrators streamline the process, here is a complete SCADA + PLC integration checklist covering planning, configuration, networking, data mapping, security, and validation.

1. Define Project Requirements

Before any wiring or programming begins, clearly define the integration scope:

- What PLCs and SCADA platforms will be used?

- Which process variables should be monitored and controlled?

- Required HMI screens, alarms, trends, and reporting?

- Expected data update rates?

- Any legacy equipment involved?

A solid requirements list prevents scope creep and ensures smoother commissioning.

2. Verify Communication Protocols

SCADA and PLCs must speak the same “language.” Confirm:

- Supported protocols: Modbus TCP, OPC UA, OPC DA, Ethernet/IP, Profinet, etc.

- Availability of required drivers

- IP addressing requirements

- Licensing implications for proprietary protocols

- Supported polling rates or subscription-based data models

Choosing the right protocol reduces latency and boosts reliability.

3. Network Preparation

A SCADA system’s stability depends heavily on the network. Check:

- Dedicated automation VLANs

- Static IPs for PLCs and SCADA servers

- Managed switches instead of unmanaged

- Redundant LAN paths (ring, star, mesh) if needed

- Firewall rules for OT network segments

- Time synchronization (NTP) across all devices

A clean network prevents 80% of integration headaches.

4. PLC Tag Structure & Naming Convention

Standardized tag names ensure consistent SCADA mapping.

Checklist:

- Use descriptive tag names (e.g., “PUMP_01_RUNNING”)

- Group tags by equipment or subsystem

- Define data types early (BOOL, INT, REAL, DINT)

- Keep naming consistent across PLC and SCADA

- Document everything in a tag list spreadsheet

A well-organized PLC program drastically speeds up SCADA configuration.

5. SCADA Tag Mapping

Importing or manually creating tags requires planning:

- Create tag groups matching PLC structures

- Match data types exactly to avoid conversion issues

- Map only relevant tags — avoid importing entire PLC databases

- Use scaling parameters for analog inputs

- Apply engineering units (°C, bar, %, L/min, etc.)

Accurate mapping ensures operators receive correct real-time data.

6. Alarm Configuration

A good alarm strategy improves operator response and prevents alarm floods.

Checklist:

- Prioritize alarms (critical, warning, info)

- Set correct thresholds

- Add hysteresis to noisy signals

- Define clear alarm messages

- Assign unique alarm IDs

- Test alarm acknowledgment behavior

- Configure alarm history logging

Alarms should inform—not overwhelm.

7. HMI/SCADA Screen Development

Good visualization improves operational efficiency.

- Use simple, clean layouts

- Add color standards for alarm states

- Use P&ID-style diagrams for clarity

- Include navigation menus

- Add real-time trend objects

- Provide manual/auto controls where relevant

- Include diagnostic screens for PLC/IO status

Focus on usability, not artwork.

8. Security Configuration

Cybersecurity is a critical part of modern SCADA systems.

Checklist:

- Role-based user accounts

- Strong passwords + expiry policies

- Disable unused ports/services

- VPN for remote access

- Firewalled separation from IT network

- Use OPC UA security features when available

- Encrypted communications where possible

Security should be built-in, not added later.

9. Data Logging & Historian Setup

If your SCADA includes historical logging:

- Select required tags for trending or reporting

- Set logging frequency

- Choose storage location (local, cloud, SQL server)

- Define retention policies

- Validate historian reads and writes

Historical data is key for analytics and maintenance planning.

10. Full System Testing & Validation

Before going live, run a complete test:

- I/O testing

- Communications load testing

- Failover testing (servers, networks, PLC redundancy)

- Alarm and event simulation

- Screen navigation checks

- Operator training session

- Documentation handover

Testing ensures a smooth handover and long-term system stability.

Conclusion

Integrating SCADA with PLCs doesn’t have to be complicated. By following this structured SCADA + PLC Integration Checklist, you can ensure reliable communication, secure architecture, clean tag mapping, and an efficient operator experience.