PLC Upgrade Case Study: Modernizing an Aging Control System

- PLC Play Ground

- 0

- Posted on

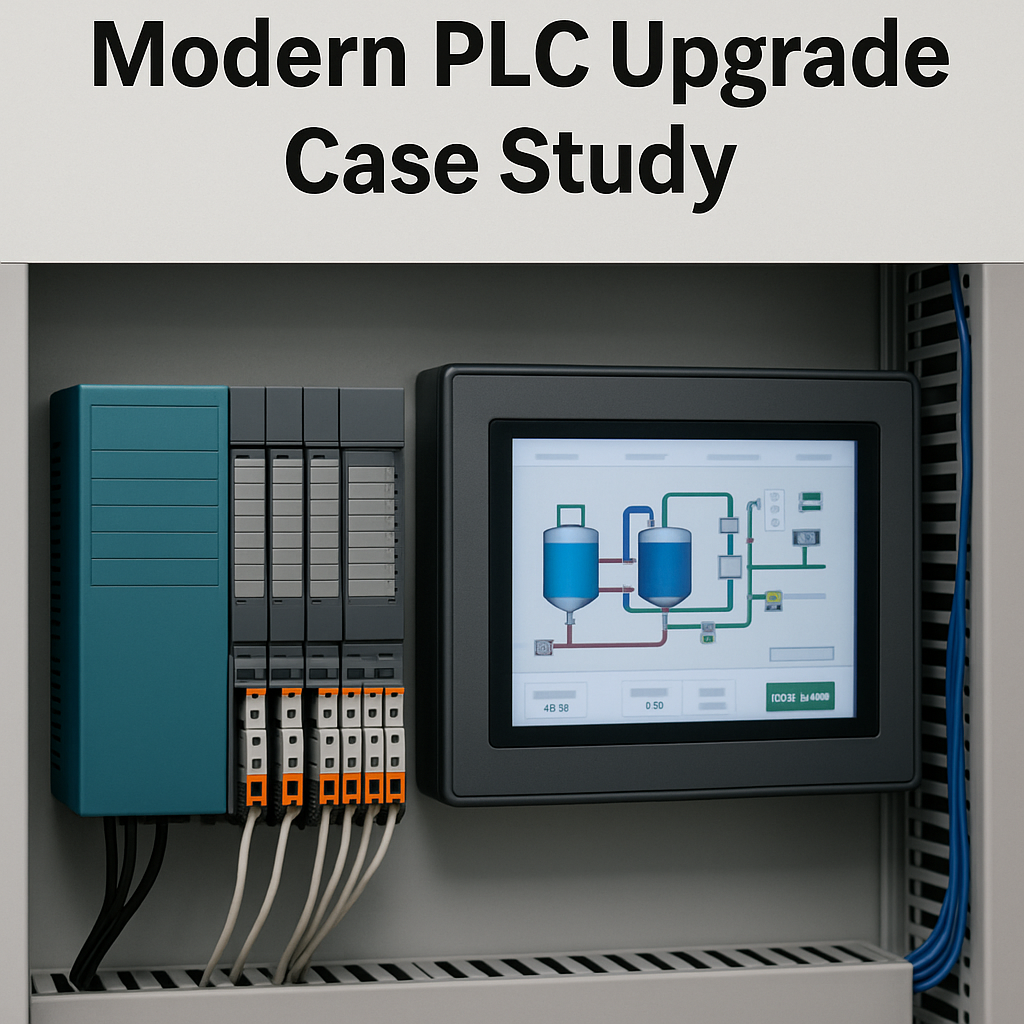

Modern PLC Upgrade Case Study

Upgrading an aging PLC system is one of the most effective ways to improve reliability, reduce downtime, and prepare an industrial process for modern automation demands. This case study walks through a real-world example of a PLC modernization project—from the problems faced with the legacy system to the successful commissioning of the new platform.

Project Overview

A mid-sized manufacturing facility relying on a 20-year-old PLC system began experiencing increasing downtime, communication failures, and difficulties sourcing spare parts. Management decided to upgrade the PLC platform to a modern, Ethernet-based system that would support advanced diagnostics, improved cycle times, and future scalability.

Challenges With the Legacy PLC

The existing PLC system presented several critical issues:

- Frequent hardware failures due to age and environmental wear

- Limited memory capacity restricting the ability to add new logic or features

- Outdated communication protocols incompatible with modern HMIs and SCADA

- Unavailable spare parts, causing extended downtime

- No remote diagnostics, requiring on-site intervention for every issue

These limitations were directly impacting production efficiency and maintenance costs.

Project Goals

The upgrade was designed to achieve the following outcomes:

- Improve system reliability and uptime

- Standardize the plant on a modern PLC platform

- Enable Ethernet communication with HMI and SCADA systems

- Enhance diagnostics for maintenance teams

- Provide room for future expansion and automation improvements

Solution: Migration to a Modern PLC Platform

The engineering team selected a modern PLC model with modular I/O, high-speed processing, and native industrial Ethernet support. The migration involved:

1. Control Program Conversion

The legacy ladder logic was reviewed, optimized, and rewritten to align with the new platform’s architecture. Redundant rungs were eliminated, and diagnostic routines were added.

2. Panel and Wiring Upgrades

New I/O modules required updated terminal blocks and labeling. The control panel was cleaned, reorganized, and retrofitted to meet current electrical standards.

3. Network Modernization

The old serial network was replaced with an Ethernet-based backbone, enabling:

- Fast data exchange

- Seamless HMI/SCADA integration

- Remote access for troubleshooting

4. HMI Replacement

A new touchscreen HMI was installed, featuring:

- Real-time alarms

- Historical trends

- PLC diagnostics

- Intuitive operator screens

5. Testing and Commissioning

Before go-live, the team performed:

- Full I/O testing

- Simulation of all sequences

- Safety interlock verification

- Shift-by-shift performance validation

Results and Improvements

After commissioning, the plant reported immediate benefits:

- 60% reduction in unplanned downtime

- Enhanced visibility through detailed diagnostic messaging

- Faster troubleshooting, reducing maintenance response time

- Improved production efficiency due to optimized logic

- Future-ready architecture for adding sensors, analytics, and IIoT features

The upgrade paid for itself in reduced downtime within the first year.

Lessons Learned

- Thorough documentation simplifies logic migration

- Investing in a structured panel layout improves long-term maintenance

- Modern Ethernet networks significantly improve system performance

- Operator training is key for leveraging new HMI capabilities

- Planning downtime windows carefully minimizes production impact

Conclusion

This PLC modernization project demonstrates how upgrading a legacy control system can dramatically improve reliability, performance, and plantwide visibility. With the right planning, testing, and execution, a PLC upgrade becomes a strategic investment that strengthens both current operations and future automation potential.