PLC Architecture: Key Components Explained (Beginner-Friendly Guide)

- PLC Play Ground

- 0

- Posted on

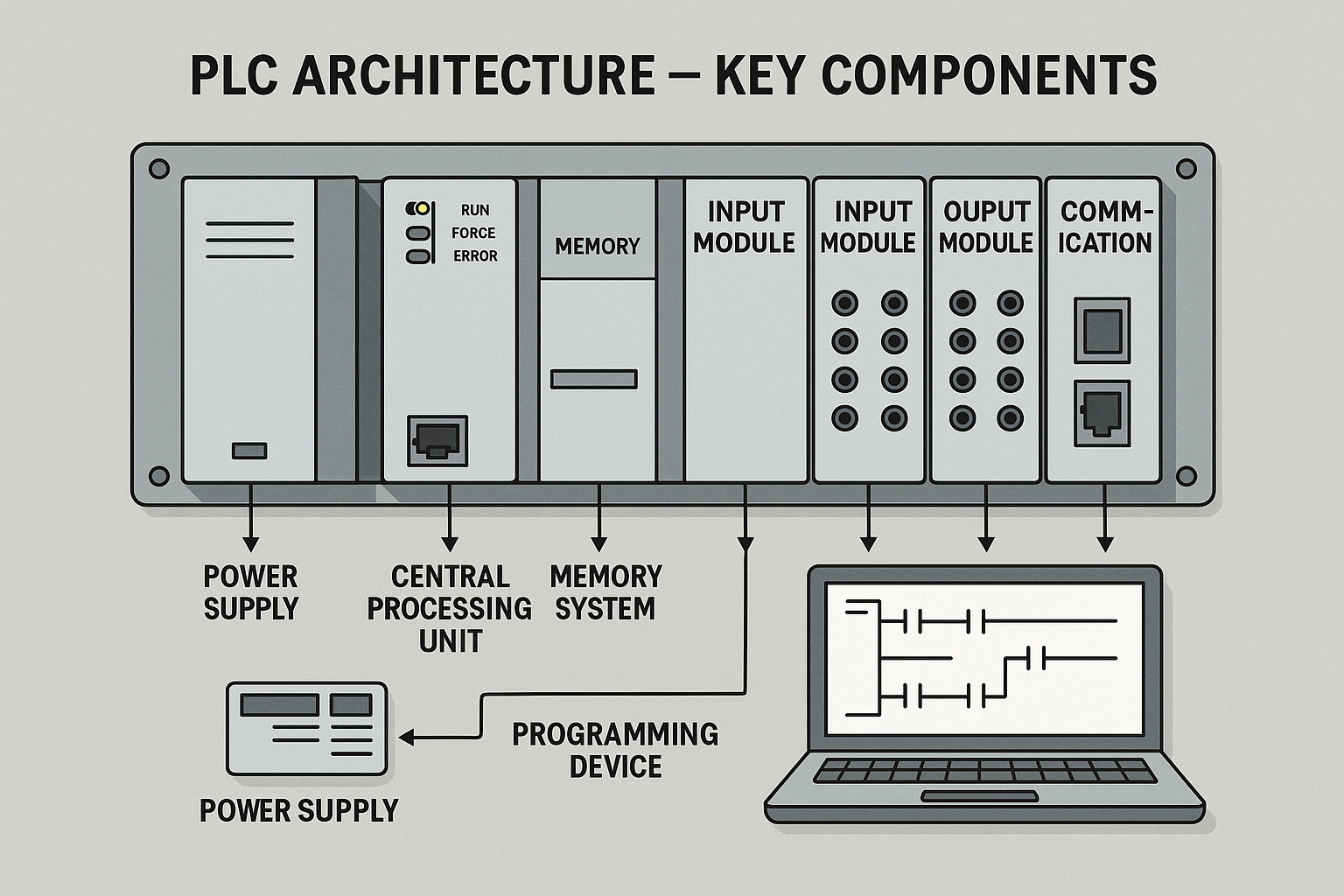

Programmable Logic Controllers (PLCs) are the central building blocks of industrial automation. Their architecture is designed to be rugged, reliable, and modular, allowing them to control everything from simple machines to complex manufacturing lines. Understanding PLC architecture is essential for engineers, technicians, and anyone working with automation systems.

In this post, we break down the key components of PLC architecture and explain how each element works together to form a complete control system.

1. Power Supply

Every PLC system starts with a power supply module.

It converts incoming AC voltage (typically 120/240V) into stable DC voltage (usually 5V, 12V, or 24V) needed to power the CPU and I/O modules.

A reliable power supply ensures uninterrupted operation in harsh industrial environments.

2. Central Processing Unit (CPU)

The CPU is the brain of the PLC.

It performs the following tasks:

- Executes the control program

- Processes input signals and produces output actions

- Manages internal memory

- Handles communication with external devices

Modern CPUs include built-in diagnostics, communication ports, and real-time processing capabilities.

3. Memory System

PLC memory stores everything required for operation, including:

- User program memory – Ladder, FBD, SFC, or structured text logic

- Data memory – Variables, status bits, registers

- System memory – Firmware, configuration, diagnostics

Some PLCs use battery-backed RAM; others rely on non-volatile flash memory.

4. Input/Output (I/O) Modules

I/O modules connect the PLC to the real world.

Types of Inputs:

- Digital inputs (sensors, switches, limit switches)

- Analog inputs (temperature transmitters, pressure sensors, flow meters)

Types of Outputs:

- Digital outputs (motors, solenoids, relays)

- Analog outputs (valves, drives, control signals)

I/O modules may be local (connected directly to the CPU) or remote (distributed across the plant via networks).

5. Communication Interfaces

Communication modules allow the PLC to exchange data with:

- HMIs

- SCADA systems

- Other PLCs

- Variable frequency drives

- Industrial networks

Common protocols include Ethernet/IP, Modbus TCP, Profinet, Profibus, DeviceNet, and CANopen.

These interfaces support real-time monitoring, remote control, and integration into Industry 4.0 systems.

6. Backplane or Rack System

The backplane provides the physical and electrical connection between modules.

It distributes:

- Power

- Communication signals

- Data bus lines

Rack-based systems allow easy expansion simply by sliding new modules into place.

7. Programming Device

A PLC must be programmed before it can control any process.

Programming devices include:

- Laptops with PLC software

- Dedicated programming terminals

- Web-based or cloud tools (in modern PLCs)

Supported programming languages are defined by IEC 61131-3, such as Ladder Logic (LD), Function Block Diagram (FBD), and Structured Text (ST).

How the Components Work Together

A simplified workflow looks like this:

- Inputs send real-world signals to the PLC

- The CPU reads the inputs and executes the user program

- The memory stores program logic and status data

- The CPU sends actions to outputs

- Communication interfaces share data with SCADA/HMI systems

- The power supply keeps everything running reliably

This integrated architecture allows PLCs to perform deterministic, real-time control essential for industrial environments.

Final Thoughts

Understanding PLC architecture is crucial for troubleshooting, system design, and performance optimization. Each component plays a vital role in ensuring reliability, scalability, and seamless integration with modern automation technologies.