Category: PLC Basics

PLC Disaster Recovery Guide: How to Protect Your Control Systems from Unexpected Failures

Programmable Logic Controllers (PLCs) are the backbone of modern manufacturing.When a PLC fails—whether due to hardware damage, corrupted logic, power issues, cyberattacks, or accidental overwrites—the result can be catastrophic: production stops, scrap increases, and recovery time can stretch from minutes to days. A proper PLC disaster recovery plan ensures you can restore your system quickly,…

Read More

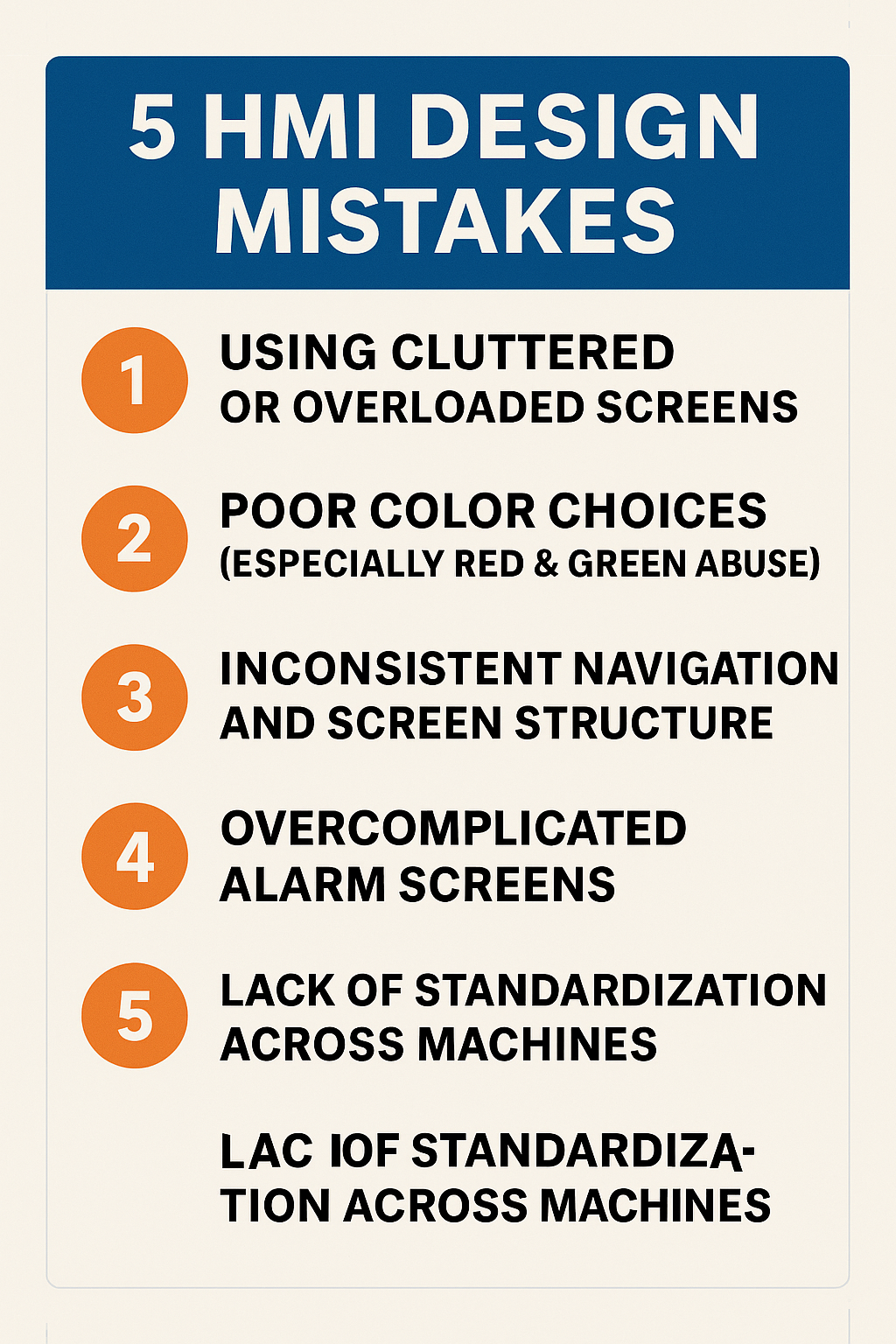

5 HMI Design Mistakes to Avoid: A Practical Guide for Better Industrial Interfaces

5 HMI Design Mistakes That Hurt Usability (and How to Fix Them) A Human–Machine Interface (HMI) is one of the most critical components in industrial automation. It’s the operator’s window into the machine.Yet many HMIs are still designed with confusing layouts, poor visibility, and unnecessary complexity—leading to downtime, operator errors, and slower troubleshooting. Here are…

Read More

When You Need a Safety PLC: A Complete Guide to Safety Requirements and Industrial Compliance

In modern industrial automation, safety is no longer optional—it’s a regulatory, operational, and ethical requirement. As machinery becomes faster, more complex, and more interconnected, traditional safety relays are no longer enough for many applications.This is where a Safety PLC (Programmable Logic Controller) becomes necessary. Whether you’re designing a new machine, upgrading old equipment, or ensuring…

Read More

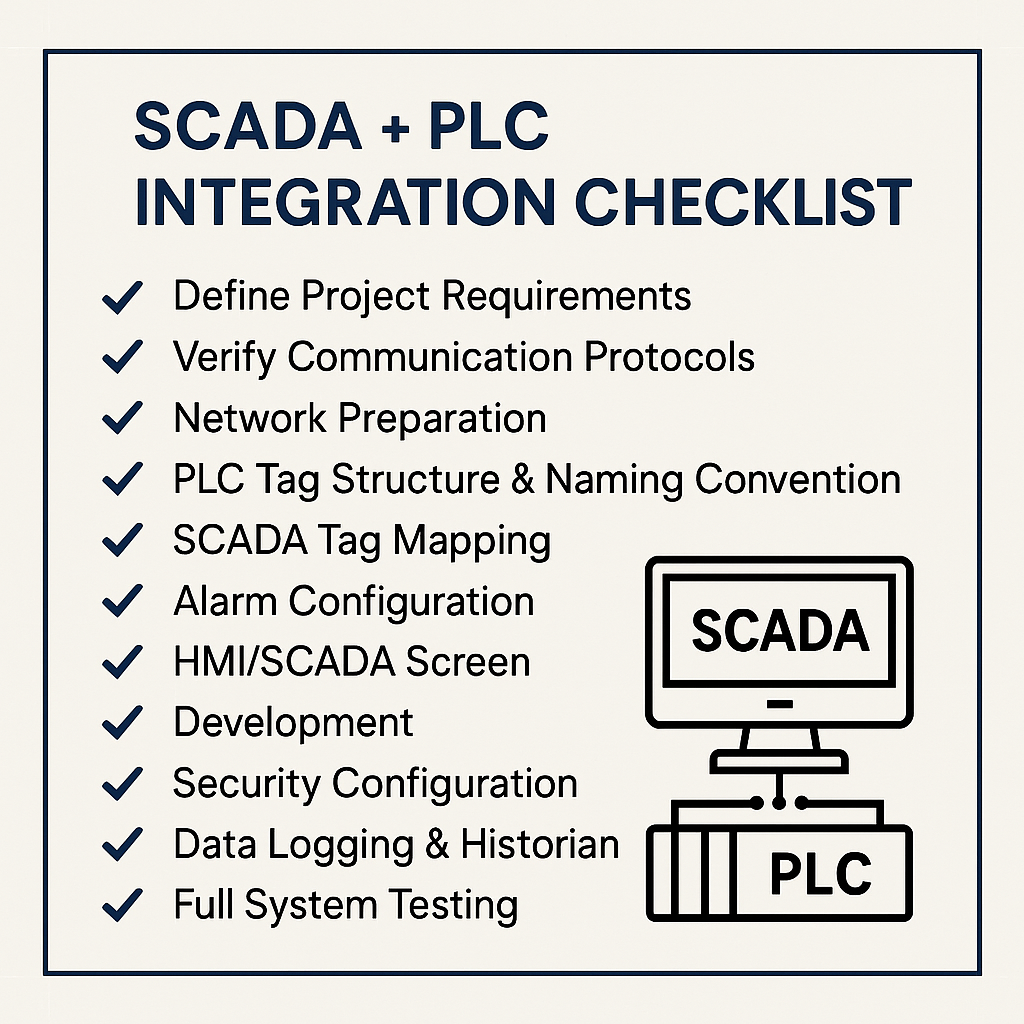

SCADA + PLC Integration Checklist: A Complete Guide for Modern Automation

SCADA + PLC Integration Checklist Integrating a SCADA system with PLCs is one of the most important steps in building a modern, reliable, and scalable industrial automation environment. A properly executed integration improves visibility, reduces downtime, and allows operators to make faster, data-driven decisions. To help technicians, engineers, and system integrators streamline the process, here…

Read More

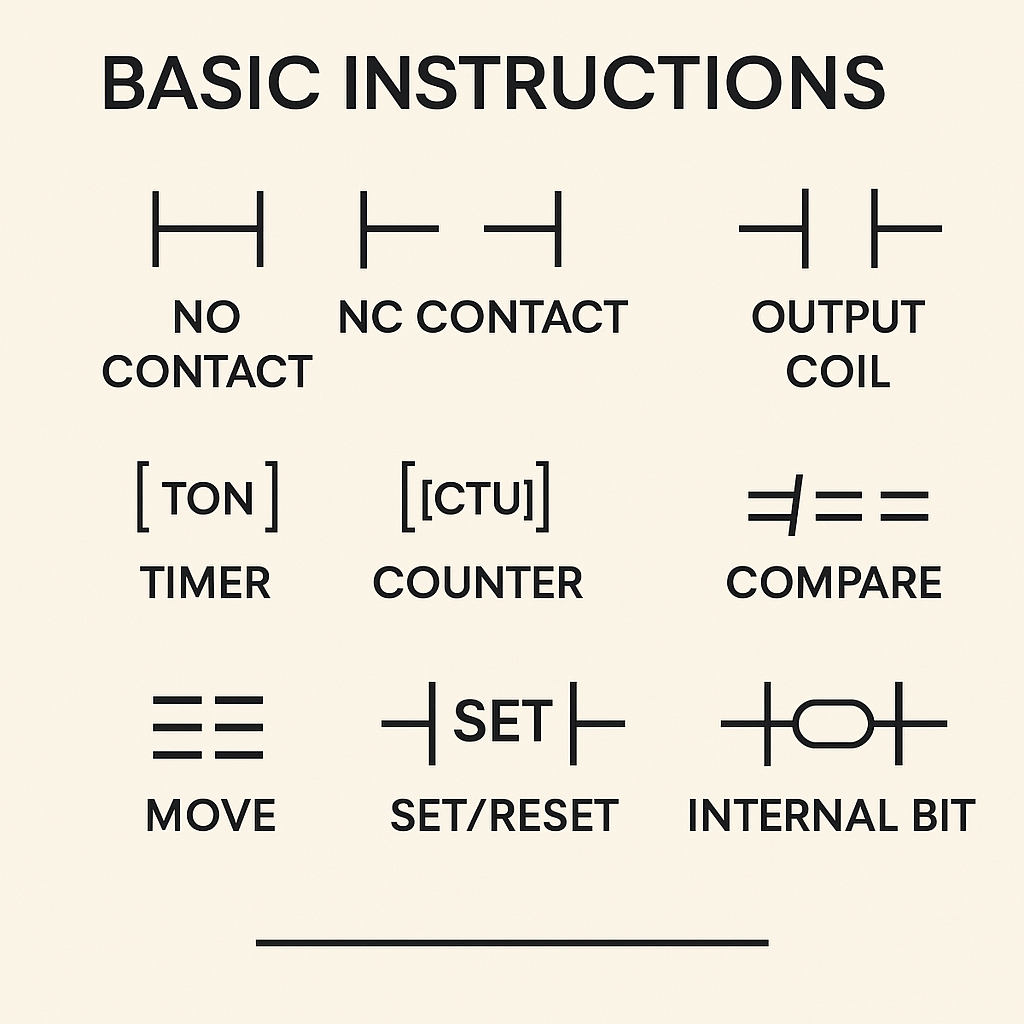

Ladder Logic Basics: Essential PLC Instructions Explained

Ladder Logic – Basic Instructions Ladder Logic (LD) is the most widely used programming language in PLC automation. Its visual, relay-style structure makes it easy for technicians, electricians, and engineers to understand how a control system behaves. Whether you’re new to PLC programming or refreshing your skills, learning the basic Ladder Logic instructions is the…

Read More

PLC Error Codes List: Complete Troubleshooting Guide for Engineers

Programmable Logic Controllers (PLCs) are reliable, but even the best systems encounter faults. When something goes wrong, PLCs generate error codes that help you quickly identify and resolve the issue.This guide provides an easy-to-understand PLC error codes list, common causes, and troubleshooting tips for brands like Siemens, Allen-Bradley, Mitsubishi, and Omron. Why PLC Error Codes…

Read More

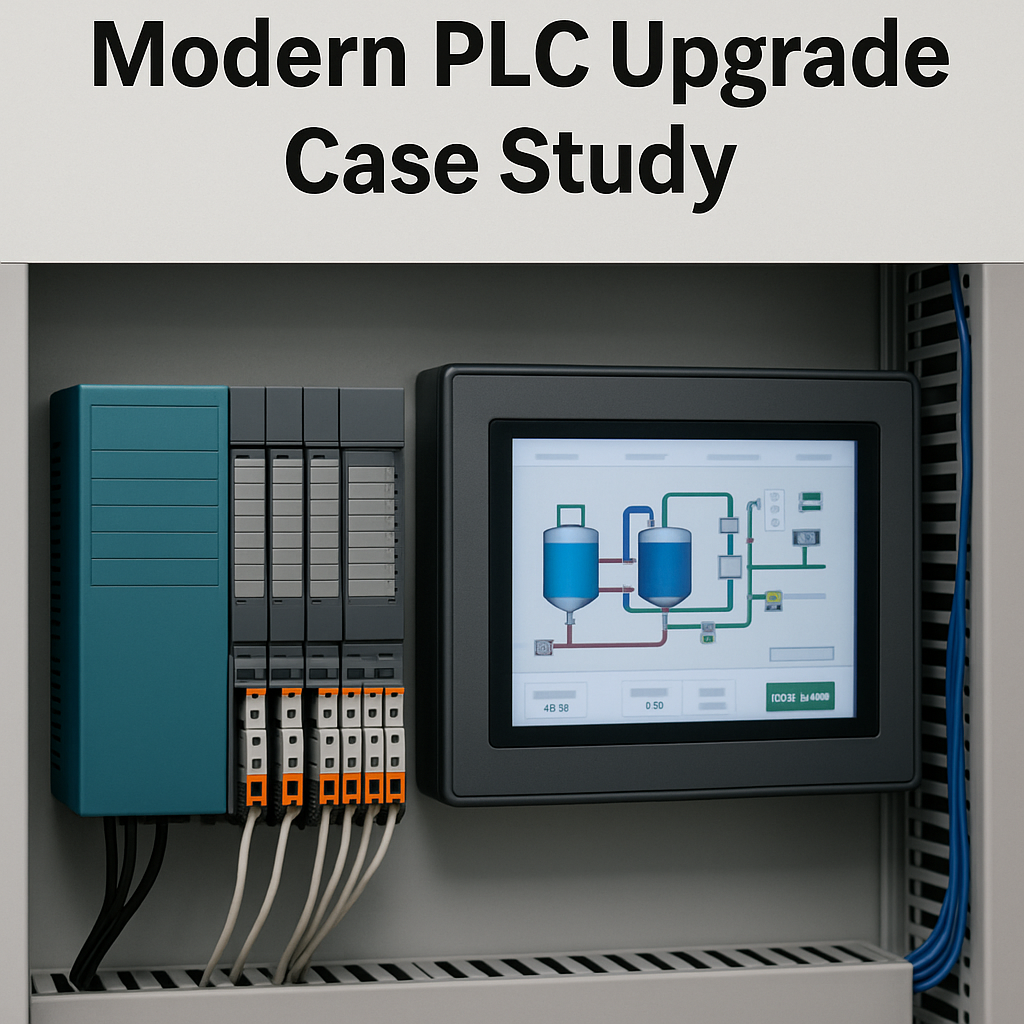

PLC Upgrade Case Study: Modernizing an Aging Control System

Modern PLC Upgrade Case Study Upgrading an aging PLC system is one of the most effective ways to improve reliability, reduce downtime, and prepare an industrial process for modern automation demands. This case study walks through a real-world example of a PLC modernization project—from the problems faced with the legacy system to the successful commissioning…

Read More

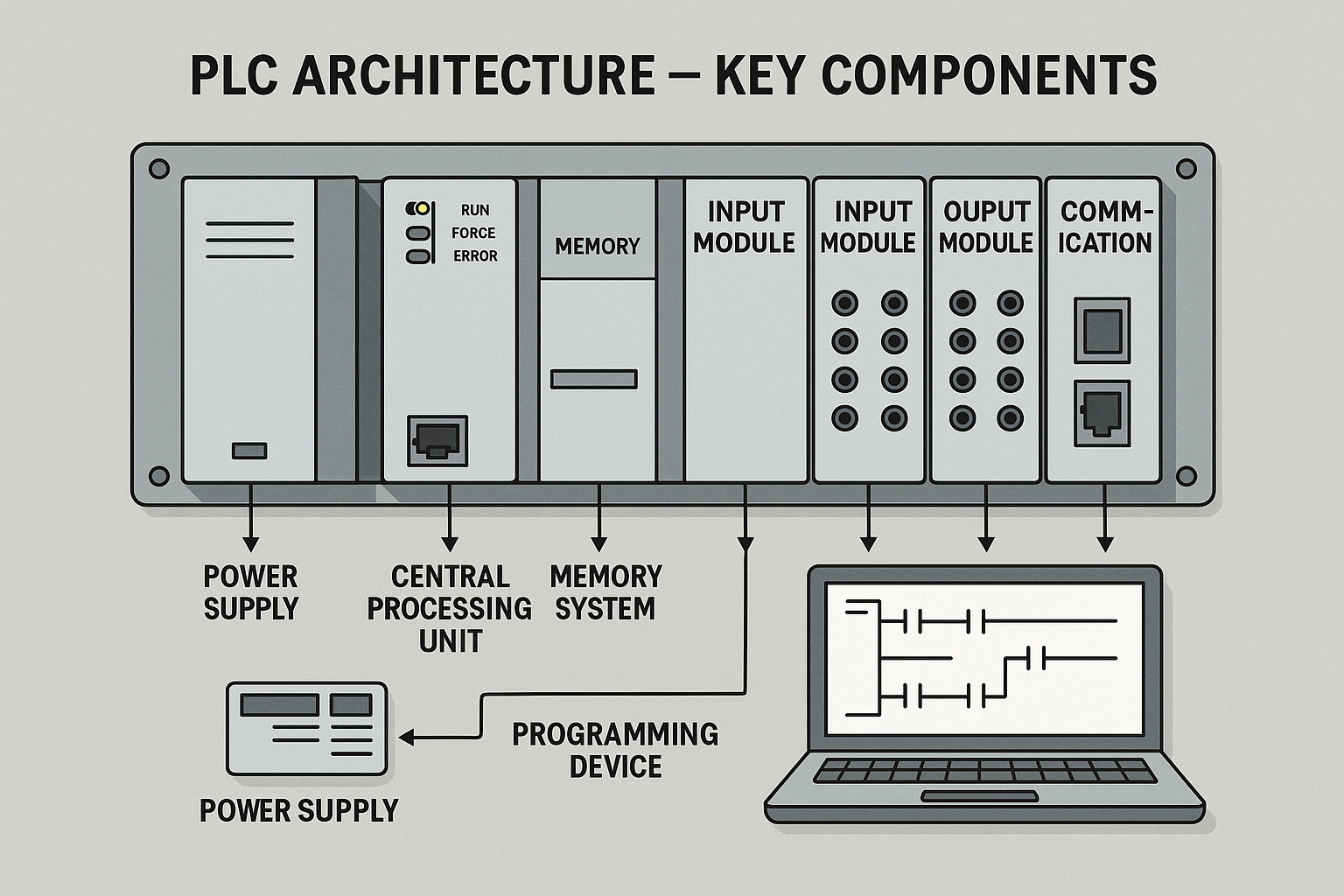

PLC Architecture: Key Components Explained (Beginner-Friendly Guide)

Programmable Logic Controllers (PLCs) are the central building blocks of industrial automation. Their architecture is designed to be rugged, reliable, and modular, allowing them to control everything from simple machines to complex manufacturing lines. Understanding PLC architecture is essential for engineers, technicians, and anyone working with automation systems. In this post, we break down the…

Read More

10 Common Uses of PLCs in Industry Today (With Examples)

Programmable Logic Controllers (PLCs) are the backbone of modern industrial automation. Originally designed to replace relay logic, PLCs have evolved into powerful, flexible controllers capable of managing complex processes with high reliability. Today, they are used across virtually every sector that relies on machinery, production lines, or automated systems. Below are 10 of the most…

Read More

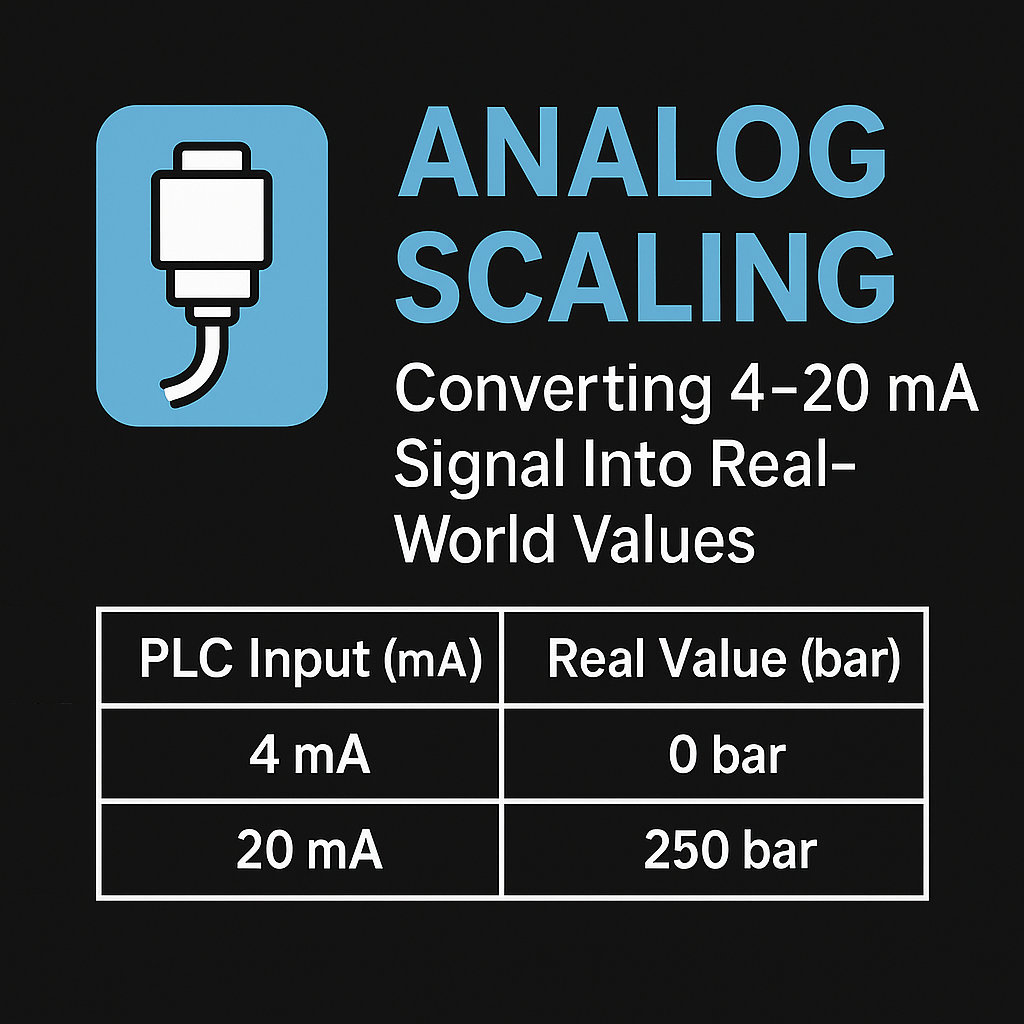

Analog Scaling: Converting 4–20 mA Signals Into Real-World Values

Many industrial sensors output a 4–20 mA signal, but your PLC can’t use that directly — it needs to convert the raw current into real-world units like °C, bar, or millimeters.This conversion process is called analog scaling, and getting it right is essential for accurate alarms, trends, and control logic. How Analog Scaling Works A…

Read More