Analog Scaling: Converting 4–20 mA Signals Into Real-World Values

- PLC Play Ground

- 0

- Posted on

Many industrial sensors output a 4–20 mA signal, but your PLC can’t use that directly — it needs to convert the raw current into real-world units like °C, bar, or millimeters.

This conversion process is called analog scaling, and getting it right is essential for accurate alarms, trends, and control logic.

How Analog Scaling Works

A typical PLC receives a 4–20 mA signal and maps it to the engineering range of the sensor.

Example (pseudocode):

raw = AI0 // 4–20 mA input

scaled = SCALE(raw, 4, 20, 0, 100) // maps to 0–100°C

This maps the minimum and maximum current values to the sensor’s minimum and maximum measurement values.

Quick Safety & Troubleshooting Tip

If your analog reading is stuck at exactly 4 mA or 20 mA, check for:

- loose or broken wiring

- a failed sensor

- a process hitting the measurement limit (e.g., tank completely empty or full)

These extreme values often indicate more than just a process change.

1-Minute Practice Problem (Solved)

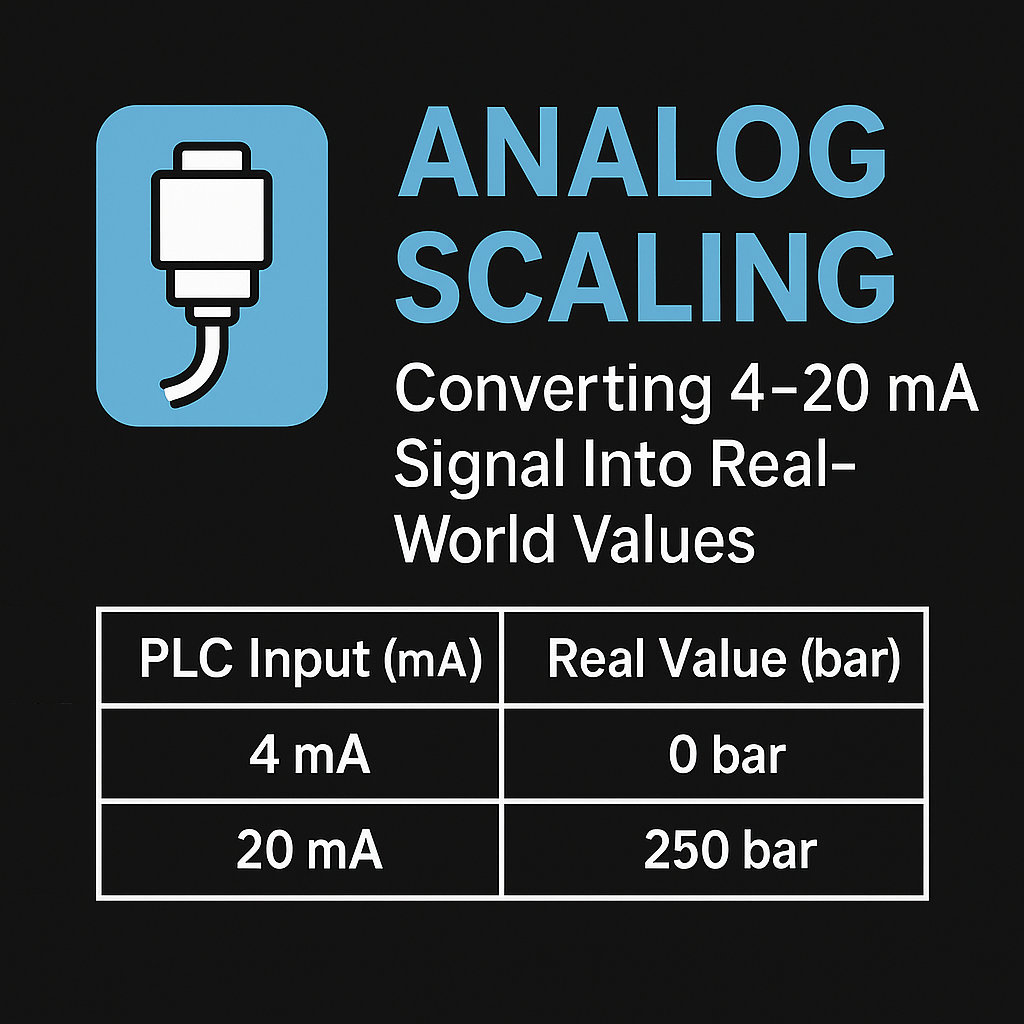

Let’s scale a 0–250 bar pressure sensor that outputs 4–20 mA.

Sensor Range:

- 0 bar (minimum)

- 250 bar (maximum)

Signal Range:

- 4 mA (minimum)

- 20 mA (maximum)

Mapping Table

| PLC Input (mA) | Real Value (bar) |

|---|---|

| 4 mA | 0 bar |

| 20 mA | 250 bar |

Scaling Formula

The basic scaling formula is:

scaled = (raw_mA - 4) * (250 / 16)

Why 16 mA?

Because the usable current span is:

20 mA – 4 mA = 16 mA

Example: PLC Reads 12 mA

Let’s calculate:

scaled = (12 - 4) * (250 / 16)

scaled = 8 * 15.625

scaled = 125 bar

Result:

A 12 mA signal corresponds to 125 bar, which makes sense — it is exactly halfway between 0 and 250 bar.