Industrial Proximity Sensors: A Simple Guide for Beginners

- PLC Play Ground

- 0

- Posted on

In modern industrial automation, proximity sensors play a huge role in keeping machines smart, efficient, and safe. Even though they might look small, these sensors are responsible for detecting objects without touching them — a crucial ability in environments where precision and reliability matter.

In this post, we will walk through what proximity sensors are, how they work, the different types you’ll come across, and where they’re used in industry. Everything is explained in clear, simple language, perfect for beginners or anyone wanting a quick refresher.

What Are Industrial Proximity Sensors?

A proximity sensor is a device that can detect the presence of an object without physical contact. Instead of touching, it uses electromagnetic fields, light, or sound waves to “sense” that something is close.

Think of it like the automatic doors in a supermarket — they open because a sensor detects that you’re near.

In industry, proximity sensors are used to:

- Count products on a conveyor

- Detect metal parts

- Ensure machine parts are in the correct position

- Prevent equipment collisions

- Improve automation and safety

Why Proximity Sensors Matter in Industry

Industrial environments can be harsh: dust, vibration, heat, oil, and fast-moving machinery. Proximity sensors are designed to handle all of that without failing.

Key benefits include:

- No wear and tear (because they don’t make contact)

- High accuracy

- Fast response time

- Long lifespan

- Reliable in tough conditions

This makes them ideal for manufacturing, packaging, robotics, and countless automation applications.

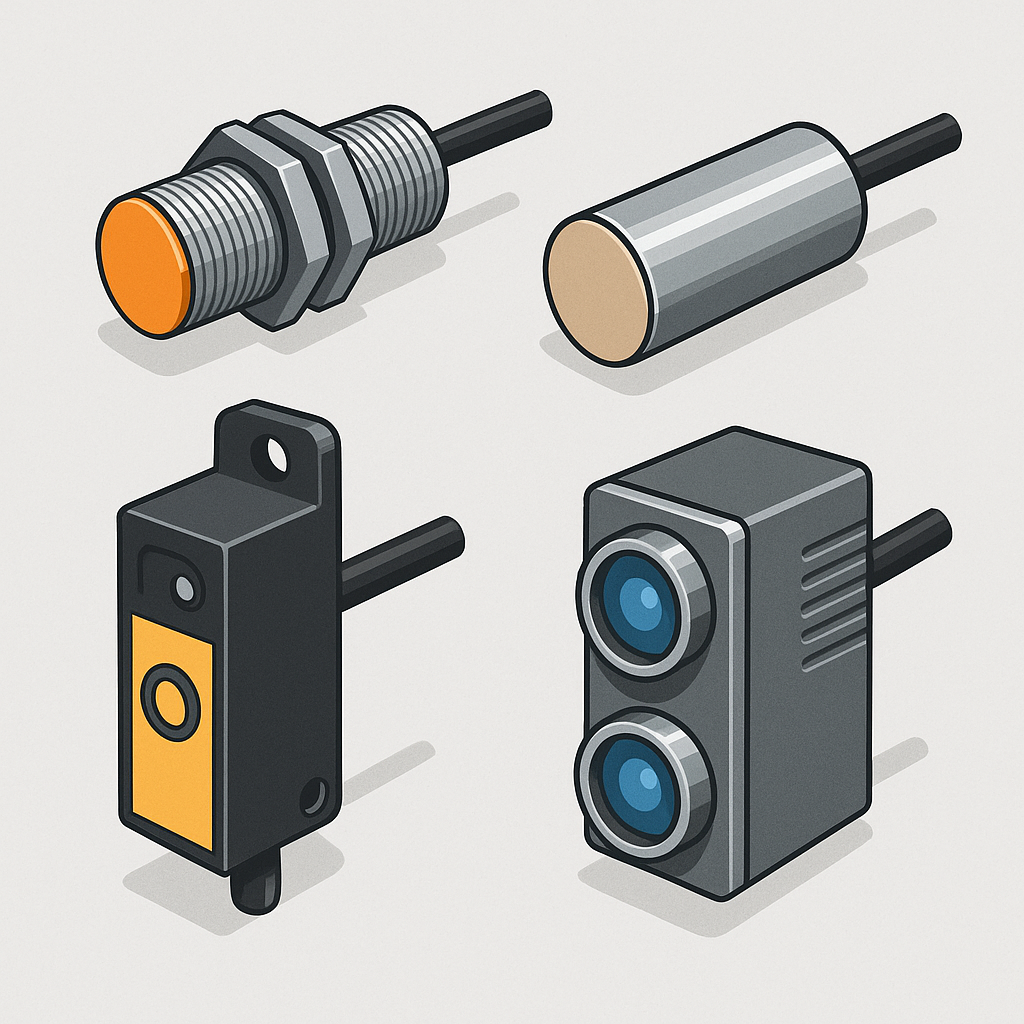

Types of Industrial Proximity Sensors

There are several types of proximity sensors, each suited for specific tasks. Here are the most common ones:

1. Inductive Proximity Sensors

- Detect metal objects only

- Extremely durable

- Resistant to dust, oil, and vibration

How they work: They create an electromagnetic field. When metal enters the field, the sensor detects it.

Typical uses: metal part detection, machine positioning, automation lines.

2. Capacitive Proximity Sensors

- Detect anything: metal, plastic, liquid, wood, granules

- Adjustable sensitivity

How they work: They sense changes in electrical capacitance caused by different materials.

Typical uses: plastic bottle detection, liquid level sensing, packaging lines.

3. Photoelectric Sensors

- Detect objects using light

- Long sensing distances

There are 3 sub-types:

- Through-beam (most reliable, longest range)

- Retro-reflective (uses a reflector)

- Diffuse (detects reflected light from the object)

Typical uses: Conveyor systems, counting items, safety barriers.

4. Ultrasonic Sensors

- Detect objects using sound waves

- Great for uneven surfaces, transparent objects, and liquids

Typical uses: Tank level measurement, distance detection, robotics.

Where Are Proximity Sensors Used?

Proximity sensors can be found in almost every automated system, including:

- Factories and assembly lines

- Robotics and CNC machines

- Packaging and sorting equipment

- Elevators and conveyor systems

- Automotive manufacturing

- Food and beverage production

Their versatility makes them one of the essential building blocks of modern industry.

How to Choose the Right Proximity Sensor

When selecting a sensor, consider:

- Material of the object (metal, plastic, liquid, etc.)

- Required sensing distance

- Environmental conditions (dust, temperature, chemicals)

- Mounting space

- Response speed

- Output type (NPN, PNP, analog, etc.)

Matching the right sensor to the right job ensures reliability and prevents machine downtime.

Final Thoughts

Industrial proximity sensors may be small, but they are essential to keeping machines running smoothly and safely. Whether you’re just starting with automation or improving existing systems, understanding these sensors gives you a major advantage.

Their ability to detect objects without contact makes them long-lasting, highly accurate, and perfect for the demanding world of industrial environments.

If you’re working on a project and need help choosing the right type of sensor, feel free to ask!